WMS/WCS Control System

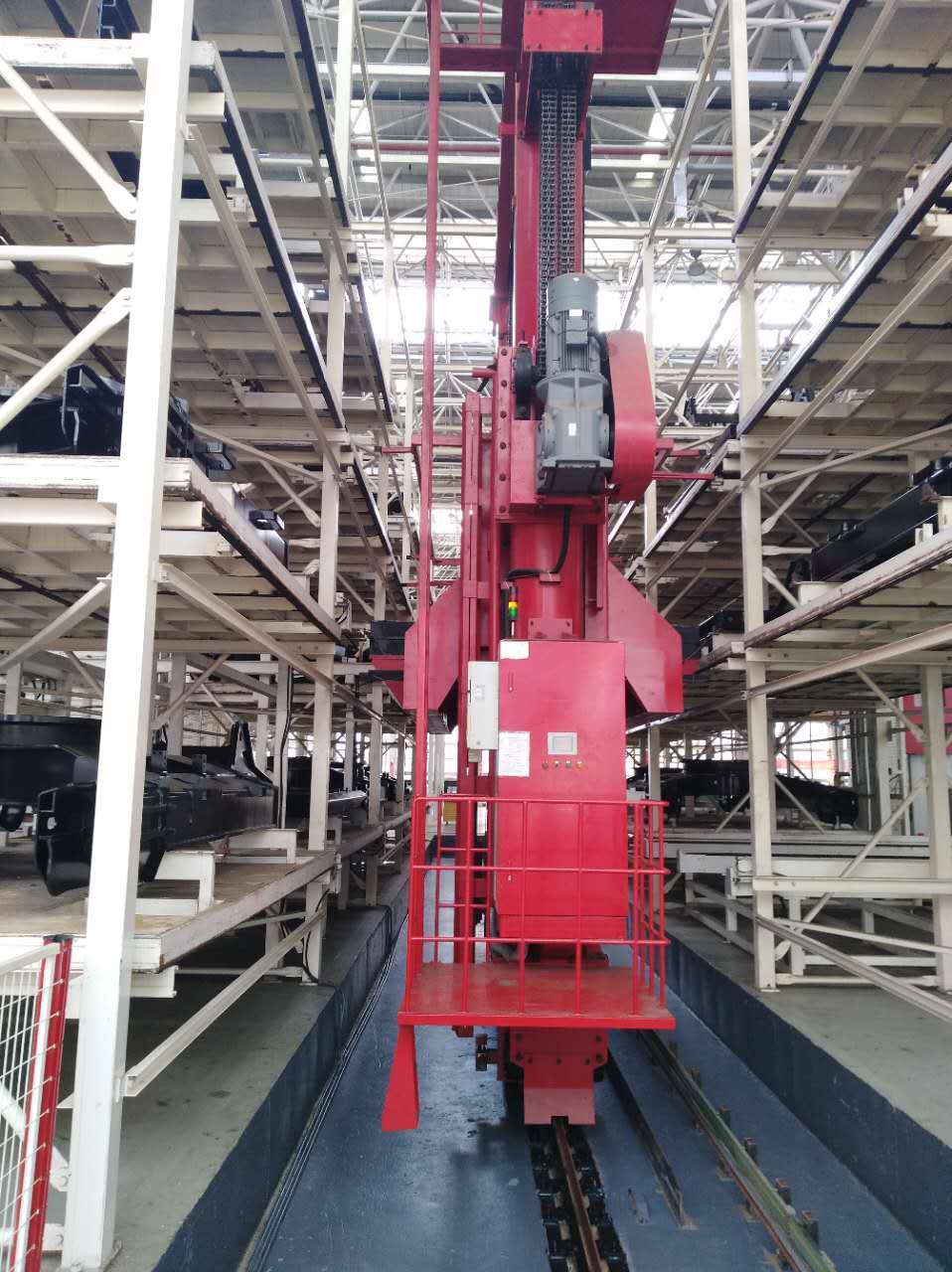

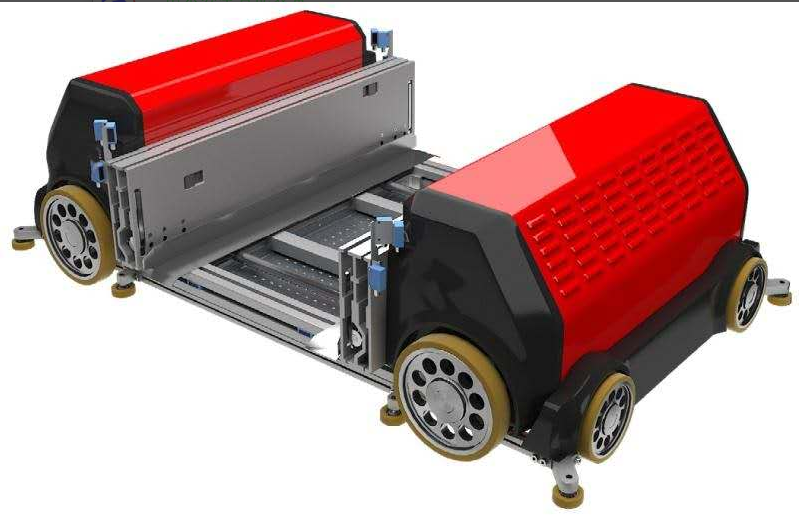

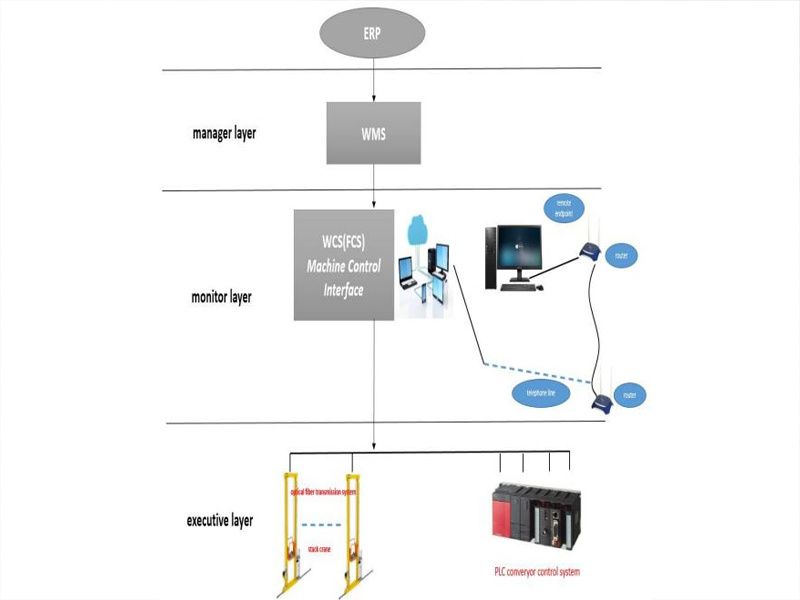

Controlling system is the brain of Intelligent storage system in charge of receiving orders from computer system, analyzing and processing then driving the system’s related devices to implement the orders.

key word:

Product classification:

Product description

WMS/WCS Control System

Controlling system is the brain of Intelligent storage system in charge of receiving orders from computer system, analyzing and processing then driving the system’s related devices to implement the orders.

Sosense intelligent controlling system’s characteristic:

Reasonable structure design: As customer’s request, we choose the suitable controlling mode and network structure to realize high efficient, reliable and expandable application’s performance.

Error management: System has self-diagnose function. When an error occurs, system will stop automatically and gives alarm.

Reliability: We choose famous imported brand spare parts for controlling system to guarantee the system working with most reliability and lowest errors.

Separate controlling mode: In the network system, each unit can run separately. If one unit of the system has problem, it does not influence other parts of the system keeping working. It simplify the system’s maintenance and adjustment. All the orders, status data of the system are processed in the general controlling system and inter-exchange with supervision computers.

WMS/WCS Control System

Multi-levels people-machine interaction.: for example each subsystem and supervision level interacted with different level of authorized people.

WMS/WCS Control System

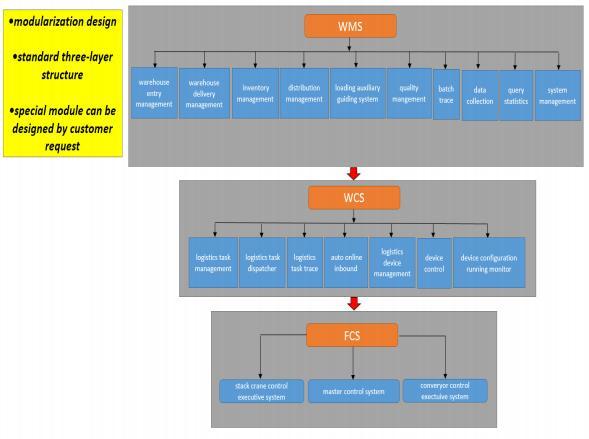

◆WMS characteristics system:

Module design;

Programmable;

Multi-layer structure;

“Plug and use”。

◆WMS main functions:

Order management;

Stock management;

Single item delivery management; Inventory;

Report and decision support;

Authorization and data safety management

◆WMS Auxiliary expanding function:

Wireless bar code system

Cargo, pallets video supervision

LED storage data display

Audio alarm system

Ground touch control supervision system