Roller Conveyor

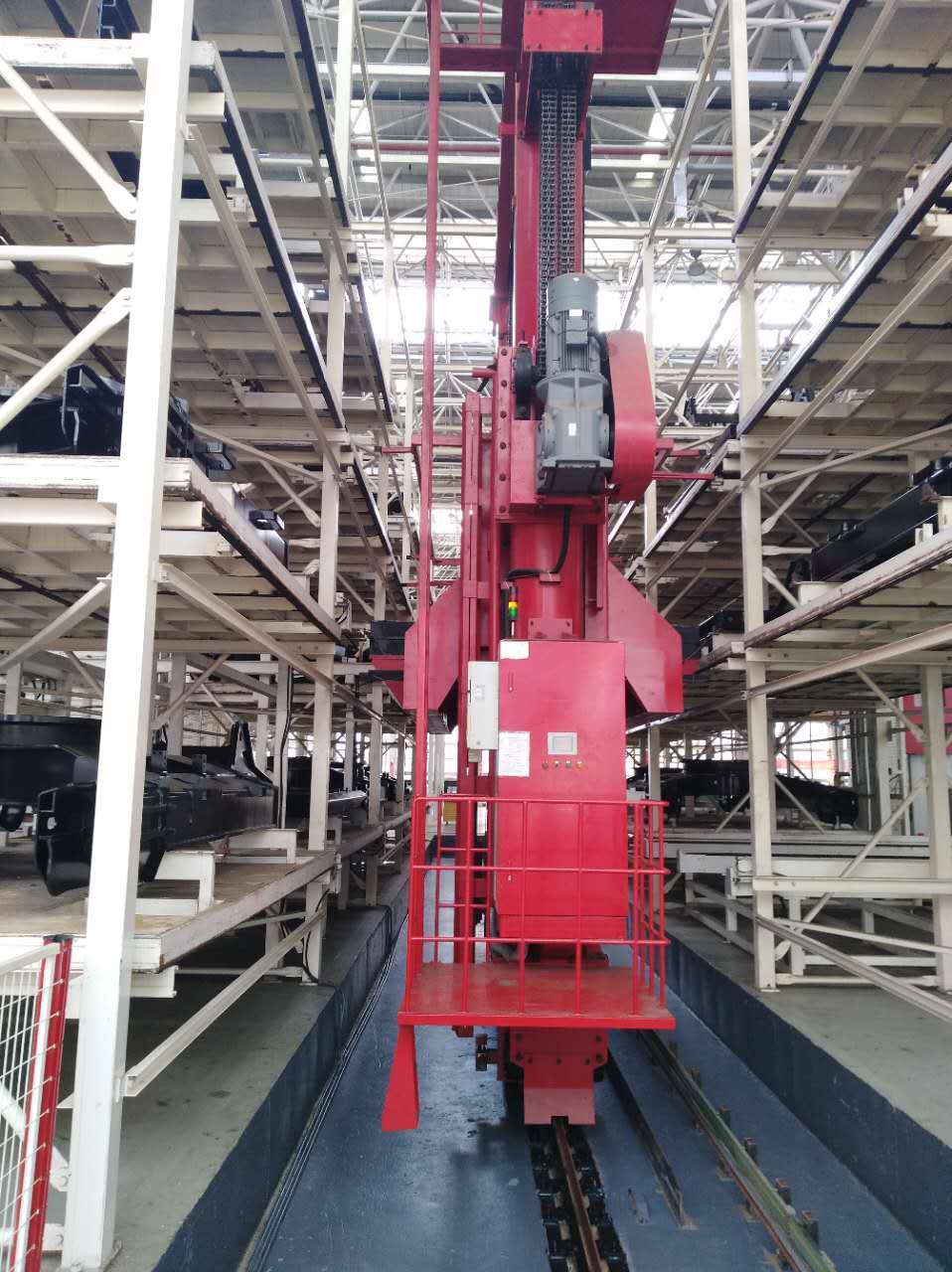

The roller conveyor is working on the transportation of all kinds of boxes, bags, pallets, etc., bulk materials, small items or irregular items need to be placed on the pallet or in the tote. It can transport a single piece of material with a large weight, or withstand a large impact load. It is easy to connect and filter between the roller lines. It can be used to form a complex logistics conveying system with multiple roller lines and other conveyors or special planes to complete various process needs. Stacking and conveying of materials can be realized by using the stacking drum. The roller conveyor's structure is simple, high reliability, and convenient to use and maintenance.

key word:

Product classification:

Product description

Features:

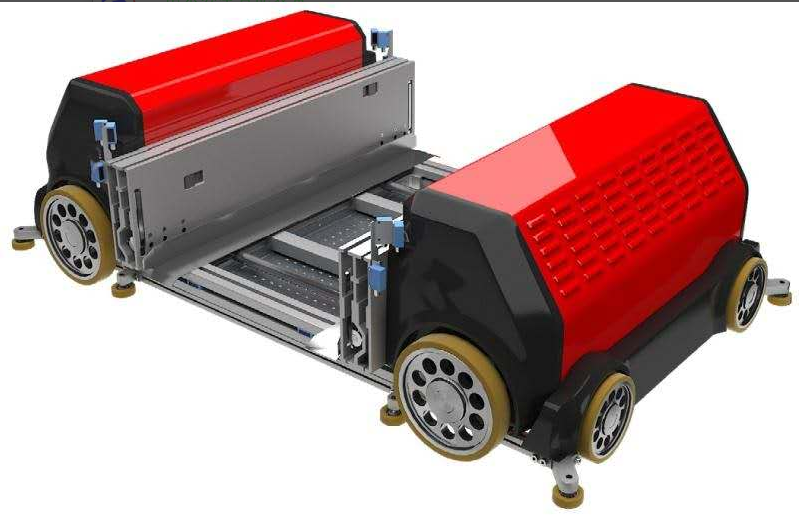

1. Various transportation configurations have small footprint and flexible expansion;

2. The direction is variable, and the conveying direction can be flexibly changed, and the maximum can reach 180 degrees;

3.S-type roller conveyor, each unit consists of 8 rollers, each unit can be used independently, or can be connected by multiple units, easy to install;

4. S-type roller conveyor is flexible, the ratio of the longest unit to the shortest state of a unit can reach up to three times;

5.S-type roller conveyor can flexibly change the conveying direction, which can be greater than 180 degrees at the maximum.

Application range:

The roller conveyor is working on the transportation of all kinds of boxes, bags, pallets, etc., bulk materials, small items or irregular items need to be placed on the pallet or in the tote. It can transport a single piece of material with a large weight, or withstand a large impact load. It is easy to connect and filter between the roller lines. It can be used to form a complex logistics conveying system with multiple roller lines and other conveyors or special planes to complete various process needs. Stacking and conveying of materials can be realized by using the stacking drum. The roller conveyor's structure is simple, high reliability, and convenient to use and maintenance.