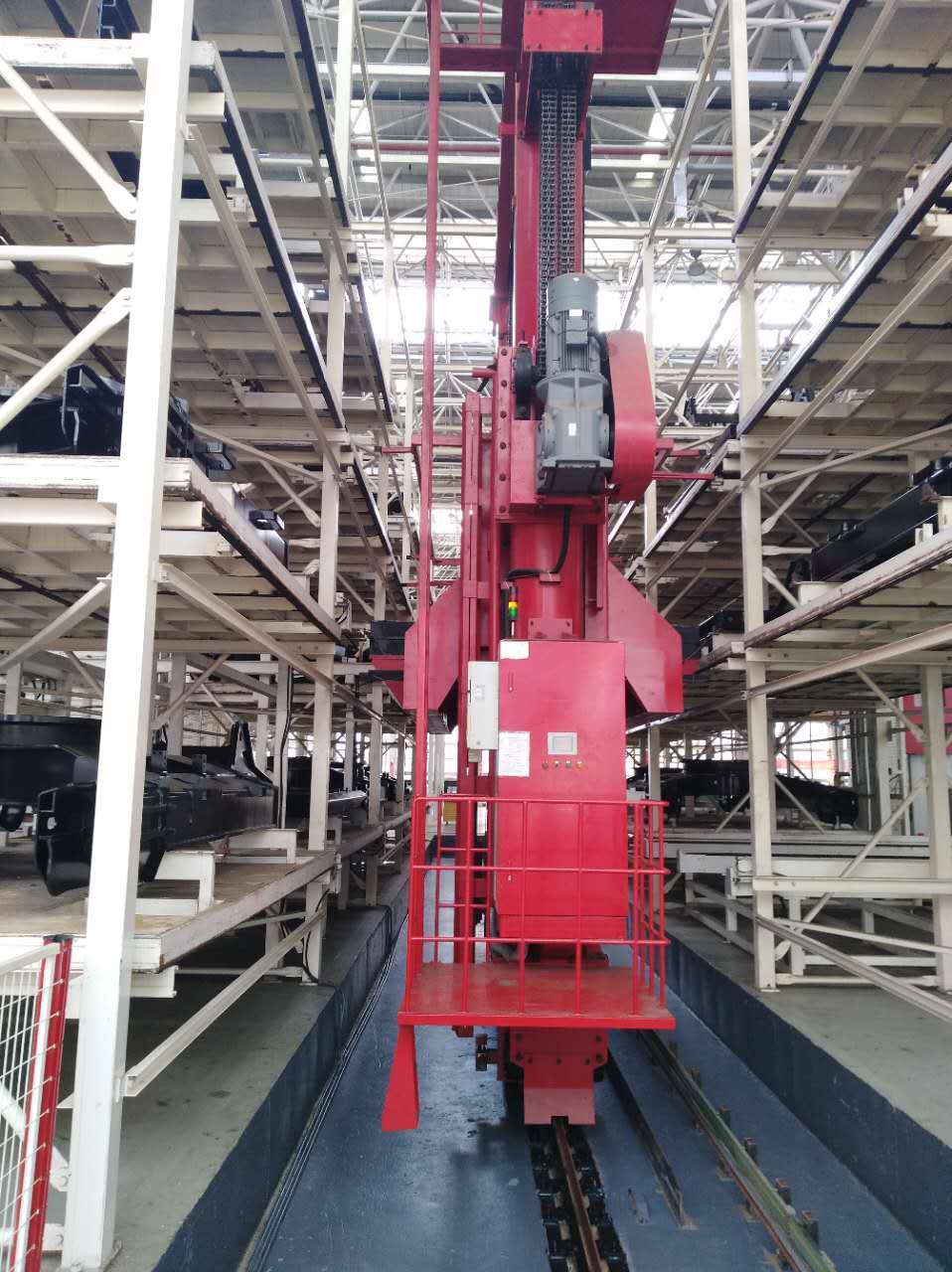

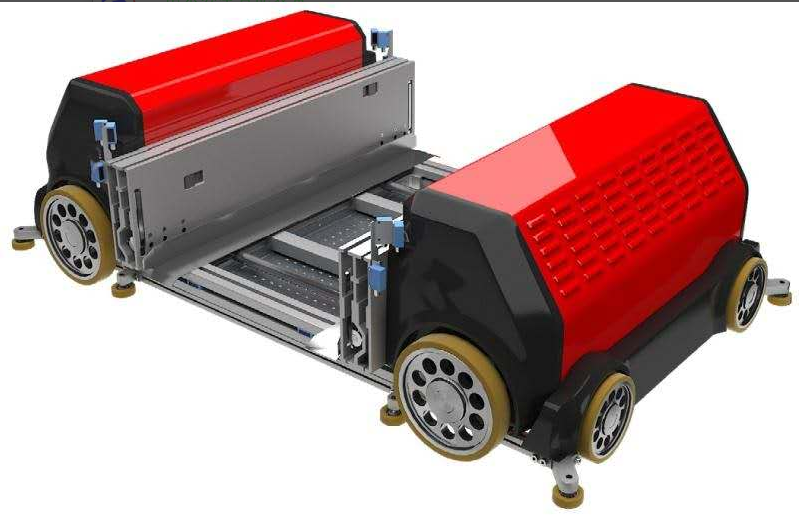

Chain Conveyor

Widely used in the automatic delivery, distribution, and downstream packaging of food, cans, pharmaceuticals, beverages, cosmetics and detergents, paper products, condiments, dairy and tobacco.

key word:

Product classification:

Product description

Features:

1. The conveying capacity is large, and the efficient conveyor allows a large amount of materials to be transported in a small space with a conveying capacity of 6m3/h~600m3/h.

2. The energy consumption of the conveyor is low. With the internal friction of the material, the material is pushed to pull, so that it can save 50% power consumption compared with the screw conveyor.

3. Sealed and safe, the fully sealed casing makes the dust seamlessly drillable, safe in operation and reliable in operation.

4. Long service life, the transportation chain made of alloy steel processed by advanced heat treatment means its normal life is >5 years, and the roller life on the chain (according to different materials) ≥2~3 years.

5. The process layout is flexible, can be arranged on the elevated, ground or pit, can be installed horizontally or climbing (≤15°), or can be installed on the same level with the machine level, and can be fed in and out more.

6. Low cost, power saving and durable, low maintenance and low cost (about 1/10 of the screw machine), which can ensure the normal operation of the main machine to increase output, reduce consumption and improve efficiency.

7. Complete series, FU series have various models such as FU150, FU200, FU270, FU50, FU410, FU500, FU600 and FU700, and can provide two types of two-way conveying.

Application range

Widely used in the automatic delivery, distribution, and downstream packaging of food, cans, pharmaceuticals, beverages, cosmetics and detergents, paper products, condiments, dairy and tobacco.