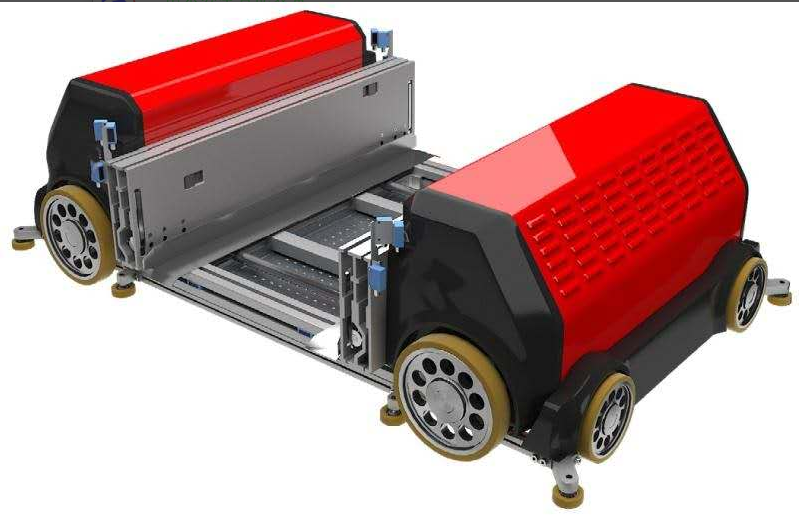

AGV

Automatic guided vehicle- AGV for short) ,equipped with magnetic or optical guiding device to run as designed routine, with safety protection and different transportation function and no need driver in the industrial transportation. Power is supplied by rechargeable Lithium battery. Normally it’s running routine and behavior is controlled by computer or by electromagnetic path-following system. Magnetic path was installed underground, AGV runs according to the magnetic signals.

key word:

Product classification:

Product description

Automatic guided vehicle- AGV for short) ,equipped with magnetic or optical guiding device to run as designed routine, with safety protection and different transportation function and no need driver in the industrial transportation. Power is supplied by rechargeable Lithium battery. Normally it’s running routine and behavior is controlled by computer or by electromagnetic path-following system. Magnetic path was installed underground, AGV runs according to the magnetic signals.

AGV moves by wheels, comparing to walk, crawl or no-wheels moving device, it is faster, higher efficient, simpler structure, better controlling and more safe. Comparing to other mode of transportation system, it no need install mechanical rails, fixed device. It is not limited by area and space. Therefore, in the automatic logistic system, it can show most automation, flexibility, efficiency, economy and smartness of production.

Specifications and parameters

|

NO |

ITEM |

|

|

1 |

AGV MODEL AGB MODEL |

RW-GT-1000SQ-AS01 |

|

2 |

Exterior dimension |

L1830mm*W1300mm*H1200mm |

|

3 |

Weight |

300Kg |

|

4 |

Running mode |

double direction drive,double direction,roll type. |

|

5 |

Guiding mode |

Magnetic stripe, Spole(width30mm, thickness 1.2mm) |

|

6 |

Driving mode |

Double group double drive differential drive |

|

7 |

Minimum turning radium |

0 ( all direction) |

|

8 |

Running speed |

10m/min-45m/min(speed is adjustable as request, considering lifetime and safety, suggested set AGV lineal speed 35m/min, turning speed 20m/min)” |

|

9 |

Running mode |

Forward, accelerate, decelerate, turn corners, stop, permanent stop, road-pick |

|

10 |

Controlling mode |

eparate control, program control, automatic path-guiding control. |

|

11 |

Position type |

RFID |

|

12 |

Stop precision |

±5mm |

|

13 |

Fixed driving load |

5t ( can be customized) |

|

14 |

Communication mode |

490MHZ |

|

15 |

Power supply |

DC48V |

|

16 |

Battery volume |

Standard 100Ah(can becustomized) |

|

17 |

Duration time |

≥10h, rechargeable times ≥600 |

|

18 |

Recharging mode |

off line charging(manual changing battery) |

|

19 |

Interface screen |

12864 LED screen. |

|

20 |

Safety protection |

Obstacle contact butter+obstacle sensor+emergency switches |

|

21 |

Power display |

when power less than23.5V, alarm for battery change. |